Description of jaw crusher

Jaw crusher is also called the tiger’s mouth. A movable jaw and a fixed jaw compose of the crushing chamber, it completes the material crushing operation just like the movement of the jaw of animals. Jaw crusher is widely used in the crushing of various ores and large materials in mining smelting, building materials, roads, railways, water conservancy and chemical industries and so on. The maximum compressive strength of the crushed material is 320Mpa.

Jaw crusher is mainly used as the coarse crusher and intermediate crusher in the mining, building materials, infrastructure and other sectors. It is divided into large, medium and small size according to the feed mouth width. The width more than 600mm is the large size, 300-600mm is the medium size, less than 300mm is the small size. Jaw crusher is easy to manufacture and works reliably with simple structure.

Two jaw plates are the work parts of jaw crusher: the first is fixed jaw, fixed on the front wall of the body vertically (or the upper part inclines outward slightly). The other is the movable jaw, inclined. It and the fixed jaw compose of the crushing chamber (the working chamber), whose upper part is bigger, while the bottom is smaller. The movable jaw plate makes periodic alternating motion to the fixed jaw plate, thus they are separated and close to each other in turn. When they are separated, the material enters the crushing chamber and the finished product is discharged from the lower part. When they are close to each other, the material between two jaw plates is crushed by being extruded, bent and split.

Jaw crusher can be divided into three types according to different swing ways of the movable jaw plate: simple swing jaw crusher, complex swing jaw crusher and integrated swing jaw crusher.

Next article :

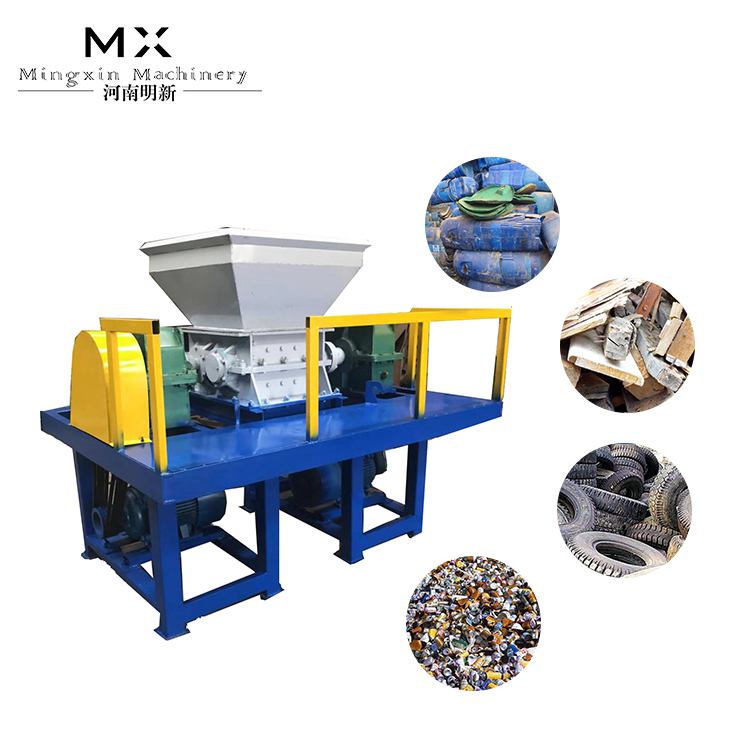

the important role of double shaft shredder reducer!