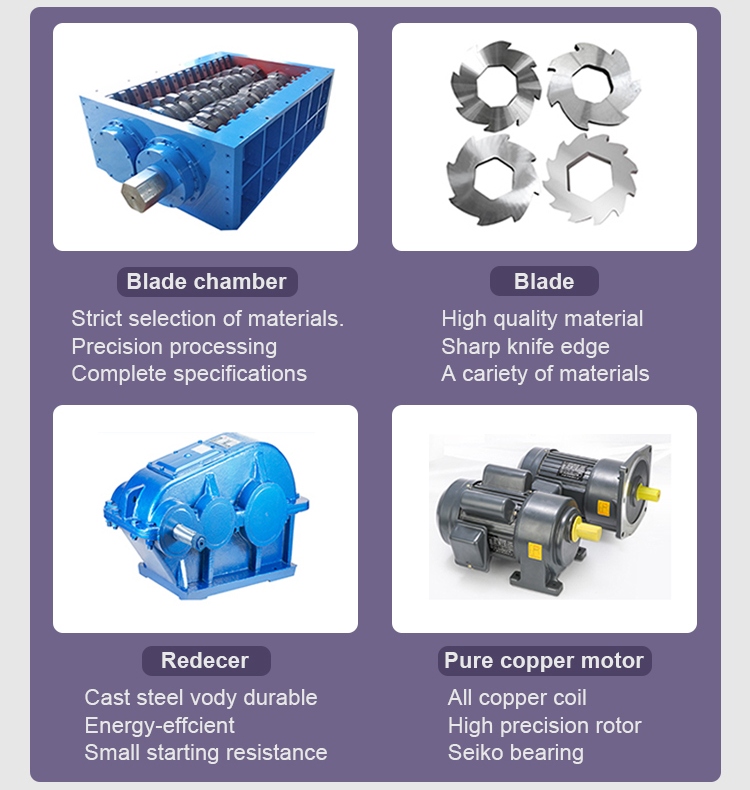

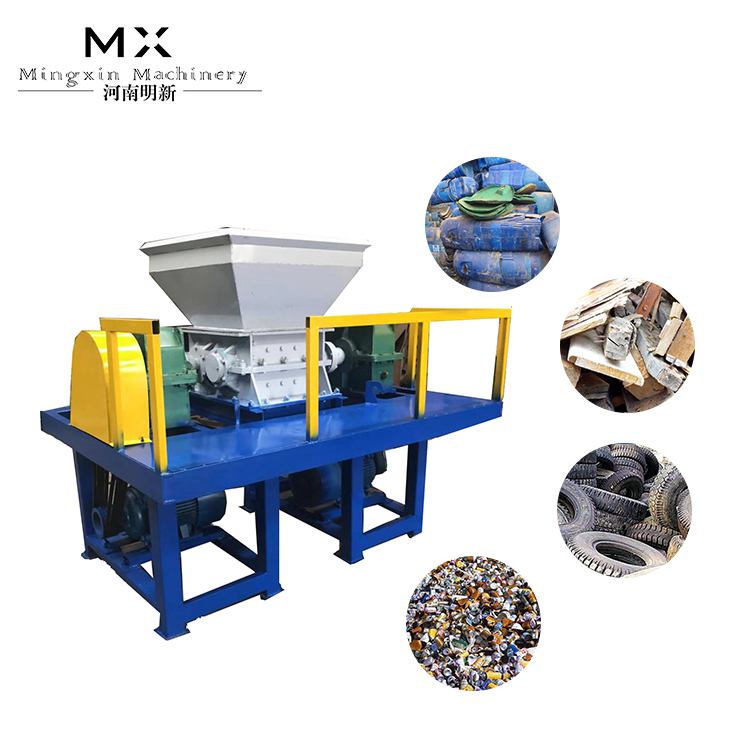

Solid waste treatment of double shaft shredder is an effective way to repair the environment and reduce pollution. With start, stop, reversing, overload automatic reversing control function, it has the characteristics of low speed, large torque, low noise. The bearing seat is of opposite type, which is easy to disassemble, assemble and replace the blade, suitable for the shredding of super-large, super-thick and non-shredding materials.

Reducer is an important part of shredding machine equipment, the correct use of reducer is an important link to ensure the normal operation of machinery, the role of reducer is to control the speed of mechanical transmission, so widely used in the field of industrial machinery. Shredder high-speed rotation of the cutter, in the deceleration of the reducer, the speed becomes slow, but this does not weaken the shredding force, the slow speed reduces the constant knife and knife in the shear friction, thus forming a low-temperature treatment system. The low-temperature treatment system formed under the operation of reducer guarantees the original performance of materials during solid waste treatment, which reduces the later treatment cycle and provides favorable guarantee for solid waste recovery.

In solid waste treatment, the capacity reduction and shredding of double shaft shredder provides high quality convenience for transportation and storage of solid waste. At the same time, there are many kinds of solid waste, which are complex in shape, size and structure, especially in performance. Therefore, in order to meet the efficiency of later recycling, it is necessary to shred the solid waste before the final coarse grain or reuse, and carry out the lasting battle of solid waste treatment to reduce environmental pollution and solid waste pollution prevention.