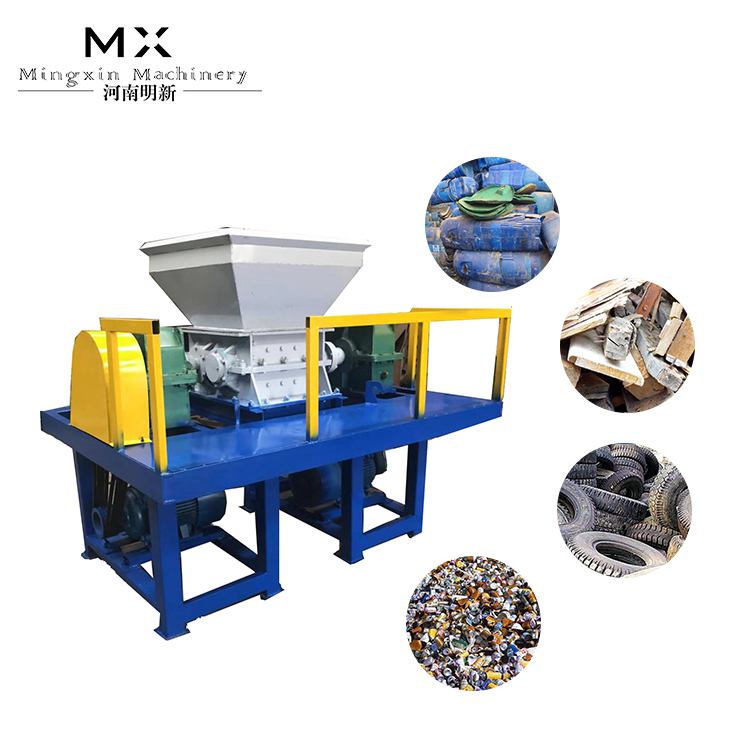

Tips on the use of wood crusher

Wood mill and other wood processing equipment are inseparable from the blade, especially wood mill, wood chip mill, sawdust mill and other blade, also have hammer; wood crusher, sawdust crusher, wood chipping machine accessories such as: screen, blade, belt pulley, triangle belt, bearing box, etc. Need to contact our manufacturers in time, to the fastest logistics to you, so as not to delay the normal work of the equipment. In fact, in such machines as wood crushing, the blades are all movable knives, fixed with screws. In normal use, it seems that the output of the machine is not as high as before, so the blades may be blunt. This cycle of use, until the blade wear out, and is the screen, if the screen is not properly installed, the screen is easy to be broken by the hammer; If you know the adjustment of the blade and the correct installation of the screen, it will increase the service life of the machine.

Eight points need to note when operating a wood crusher:

1. First in the connection of wood shredder power supply, see whether the correct direction.

2. When installing and changing the tool, the edge of the tool extends 2-4mm from the plane of the tool disc, and then tighten the bolt. If the pressure bolt thread is worn, it should be replaced immediately to prevent damage to the slider disc nut.

3. Change the wood crusher blade expansion, must be the same length. ;

4. By adjusting the length of the knife, particles can not reach the ideal, change the different aperture of the wood mill screen.

5. It is strictly forbidden to put the wood with stones and nails into the wood crusher to prevent the knife and inner parts from being damaged.

6. Pay attention to check hammer piece bolts, found loose, immediately tighten, hammer piece and bolts wear seriously, should be replaced.

7. Often used wood crusher should check the bearing butter is missing. Should 3-4 hours add butter once, add butter is not too much.

8. Sharpening Angle is straight from 28 ° to 30°. It is strictly prohibited to grind into a convex surface, which will cause the steel blade to disengage or partially uncover the steel.