Impact crusher main advantages

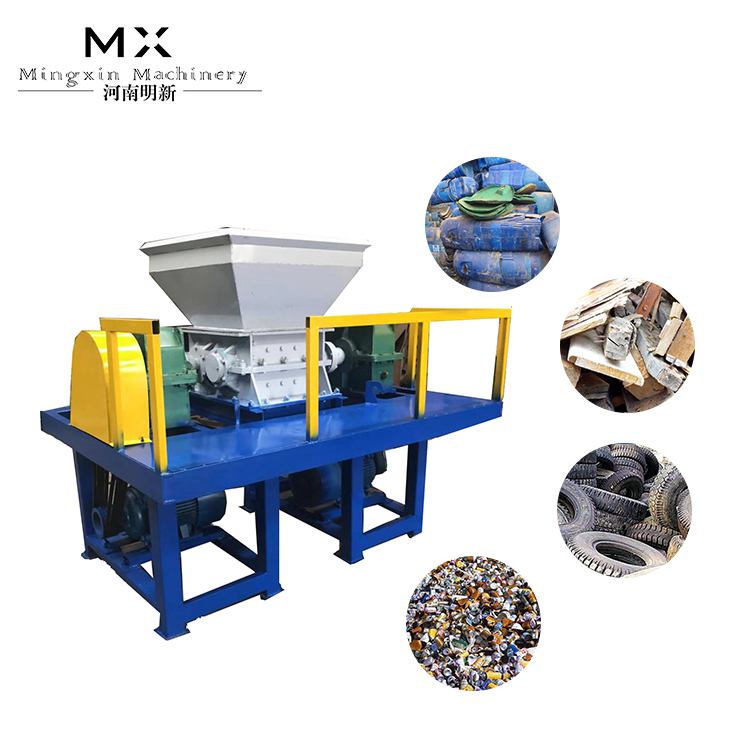

Impact crusher as secondary and tertiary crushing work, its suitable materials with larger range, the largest feed up to 1400 mm or so, discharging granularity 30-150 mm, the products are used in water conservancy and hydropower, high speed railway, building materials, mining and other basic construction industry construction sand and gravel aggregate processing in the crusher of urban construction waste treatment, and finely homework. Impact crusher structure is relatively simple, crushing materials in the process of energy consumption and power consumption is small. Because the counterattack crusher USES the counterattack crushing principle, the material strikes back and forth in the crushing cavity, achieves the crushing material goal. Therefore, the impact crusher has a larger crushing cavity, the material in the crushing cavity has a larger movement space, can better achieve the crushing of materials. Because the crushing is relatively large, the size of the material can be controlled by adjusting the counter plate, so it has unique advantages in terms of uniform product size.

Impact crusher is usually equipped with discharge clearance adjustment device, which can be used to change the number of impact of materials in the production process, so as to change the particle size of finished materials. If in order to meet the requirements of particle size of some materials, the particle size of finished materials can be changed by adjusting the clearance between the plate and the plate hammer, so as to realize different requirements of materials in actual production and reduce the investment of equipment.

In short, the advantages of counterattack crusher are that it can save equipment investment, simplify crushing production process, reduce energy consumption, improve processing capacity, improve equipment efficiency, etc., which can be better applied to various actual crushing projects.

Next article :

The advantages of heavy hammer crusher