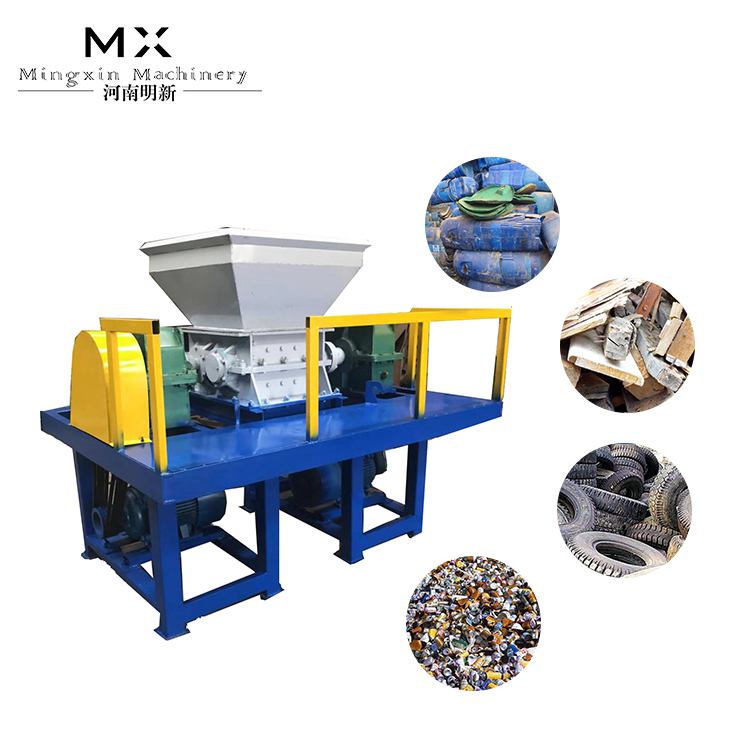

Fully automatic waste paper packer has the characteristics of good rigidity, good stability, beautiful appearance, convenient operation and maintenance, energy saving and low investment cost of basic equipment. It is widely used in various waste paper mills, waste material recovery companies and other units. It is suitable for recycling waste paper and plastic straw. It is a good equipment to improve labor efficiency, reduce labor intensity, save manpower and reduce transportation costs. Fully automatic waste paper packer has a wide range of applications, but the maintenance is not in place, there will be some minor faults, affecting the packaging process, often, the noise is very high. So, what are the common maintenance methods of automatic waste paper baler? Next, I will introduce the use and maintenance of the automatic waste paper packer.

The maintenance of automatic baler often determines the service life of the machine itself and the operation efficiency of the machine. In fact, the automatic baler itself is also attributed to the type of high machinery. The technological requirements of the machine are very high. The structural parts of the machine can be manufactured in batches only after strict inspection, and the internal incomplete meeting. It often leads to problems and faults in automatic packing machine.

Next, what should we do if there is a line fault in the use of the automatic waste paper packer?

1. Faults in Electrical Circuits

(1) The electric circuit of the automatic packer is broken, the electromagnet is not energized, and the electromagnet is energized without control signal.

(2) Poor welding of electrodes, loosening and re-welding of joints, and welding of joints.

(3) Voltage is too low or unstable to check the voltage at both ends of the electromagnet. Its change value should be within 10 of the rated voltage.

2. Electromagnet coil heating to burnout

(1) Coil insulation is not good, resulting in leakage to replace the coil.

(2) Unqualified core of electromagnet can not be absorbed and replaced.

(3) The push rod is too long, the core of the electromagnet can not be sucked in place, and the push rod can be trimmed to the appropriate position.

(4) When the electromagnet works at high frequencies, the dry friction of the core causes thermal expansion, which causes the core to be stuck and repaired or replaced.