high efficiency soyabean sunflower palm oil refining machine

The crude oil is pumped into the oil refining pot for degumming and neutralization. When the oil and soap are obviously separated and sink rapidly, stop stirring, stand still, and then suck out the upper clear oil to the water washing tank. The soap foot is put into the soap foot bucket through the bottom emptying pipe. When the soap foot contains more oil, stop putting the soap foot, and the soap foot is pumped into the soap foot tank by the pump. The remaining oil in the refining tank is mixed into the next tank to continue. The clean oil transferred in the refining tank is washed with water and then goes to the decolorization tank for adsorption and decolorization. The decolorized oil is pumped to the plate and frame filter for filtration, and then transferred to the polishing filter for further filtration.

After cooling by the cooler, it enters the decolorized clear oil tank. The decolorized clear oil is sucked into the deodorization pot through the heat exchange tank for deodorization. The deodorization is carried out under the residual pressure of 3-5 Torr. The deodorized oil is put into the heat exchange tank. After discharge, the next pot of decolorized clear oil is sucked into the deodorization pot through the heat exchange tank and enters the next round of deodorization. After heat exchange, the deodorized oil in the heat exchange tank is cooled with cold water, pumped out for polishing and filtration, and then enters the finished oil tank.

Last article :

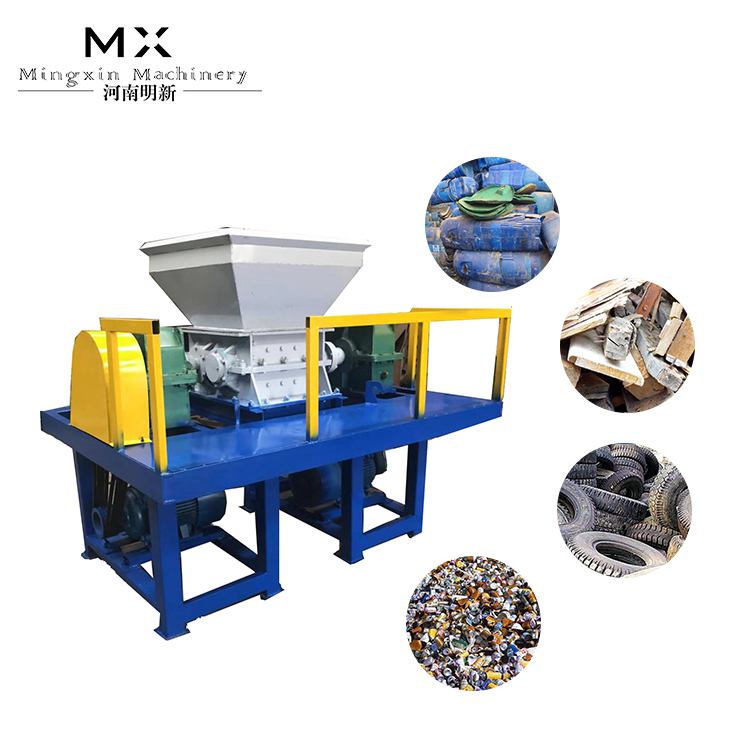

plastic crusher tire shredder machine